New gravel technology holds answers to upgrading rural road network

Sifelani Tsiko

Agric, Environment & Innovations Editor

The improvement and construction of the country’s gravel and earth roads which make up nearly 90 percent of Zimbabwe’s unsurfaced (78 200km) roads is still crying out for a low–cost and proven sustainable solution.

When engineers, scholars, policy makers and other stakeholders discuss road improvement or road rehabilitation of gravel roads, they all too often talk about asphalting or tarring or alternatively watering and grading of the road surface.

Experts say the problem with these antiquated solutions is that neither are sustainable, cost effective or long-lasting.

Road construction engineers say an asphalt or tar surface is porous, not water resistant and is susceptible to erosion and crack formation later leading to potholes.

Tarring and the traditional watering and grading of gravel and earth roads require a very costly maintenance routine including specialised equipment even for minor repairs.

In the country’s rural areas, watering and grading leads to a massive waste of water and grading can only be executed so many times until the road is graded down to bedrock.

Resources for improving gravel and earth roads in Zimbabwe are tight and this has left most roads in extreme disrepair and in poor condition.

This has made connectivity and accessibility to most rural parts of the country difficult.

Efforts to promote socio-economic growth in trade, agriculture, tourism and other key sectors have been dented.

Many rural communities have been deprived of many social, environmental and economic benefits that arise from upgraded road networks in their communities.

However, it’s not all gloom and doom for the country’s 98 000km road network – made up of 89 percent (78 200km) unsurfaced gravel and earth roads while the sealed road network — mainly in urban areas — and the main highways constitute 18 percent or 17 846 kilometres.

New investors and contractors are taking a new perspective and a different approach.

Mr Tichawona Shumba, managing director of Dreamverse (Pvt) Ltd, a local company that has exclusive rights to distribute an American product, Ecoroads in Zimbabwe has now been granted approval by the Ministry of Transport and Infrastructural Development to test the feasibility and practicability of building rural roads using a gravel road stabilisation solution or formula.

“We need to embrace new technologies such as the Gravel Road Stabilisation Solution to try and reduce cost and impact on our environment,” he said.

“For a very long time, there was little uptake of new innovative solutions to rehabilitate and construct our rural roads.

The methods that we have always used for our rural gravel roads require a very costly maintenance routine including specialised equipment even for minor repairs. Watering and grading leads to a massive waste of water and grading can only be executed so many times and this is quite costly to our fiscus.”

Mr Shumba

The gravel road stabilisation solution was once approved by the Department of Roads in the past and demonstrations were done along Mutoko road near Chivake River Bridge and other three areas in the country.

Shumba’s Dreamverse company is now spearheading fresh trials in Goromonzi and at few other mining areas to promote this new technology at a time when the country is hungry for innovative solutions for road infrastructural development.

“Our company has secured distributorship for a gravel road stabilization solution for Zimbabwe’s rural and other private gravel road networks,” he said.

“The solution is designed to reduce road maintenance costs up to 60 percent”

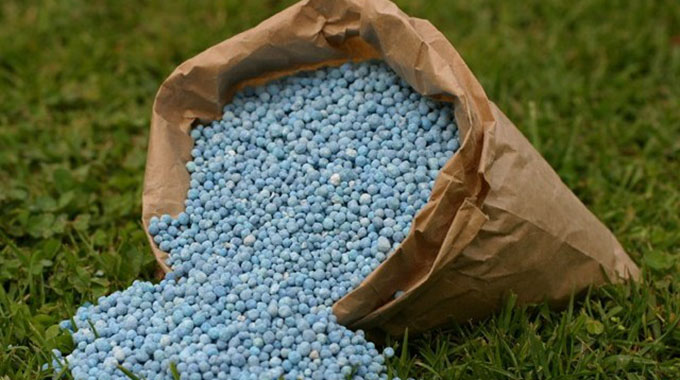

The gravel road stabilisation solution or formula, he said, uses a multi-enzyme road base construction and soil stabilization chemical product that helps increase the strength, density and durability of roads in an efficient and inexpensive way.

“What does this entail? The process involves the use of a chemical that is delivered in 20 litre canisters which is mixed with water using a bowser. The gravel road is first prepared and soil tests done. Once the application has been sprayed on to the prepared gravel road, it mixes with soil.

“The soil is then compacted and left to dry for 72 hours. Thereafter, the road is ready for use.”

This process, he said, uses locally available materials – mainly soil. It does not use cement or stone aggregates.

Once the road has been compacted, Mr Shumba, said the cost of gravel road maintenance could be cut by between 50 to 60 percent.

“Most of the rural gravel roads are maintained on an annual basis and when you use the gravel road stabilisation process, maintenance is only done once in every 4 to 5 years,” he said.

“Instead of the DDF using money to maintain the roads every year, the resources could be saved and channelled for other uses. It’s non-toxic and even if it flows into water bodies it does not affect humans, animals or marine species.”

This technology has been successfully adopted in 29 countries – mostly European, including Israel and more recently, South Africa, Kenya, Uganda, Ghana and Tanzania.

In Tanzania, a private contractor has been allowed to test the technology on a 1km stretch.

“Currently, I am holding discussions with the Zimbabwe Association of Rural Councils to do a demo in Goromonzi. We are going to do a demo on a 1km stretch and if all goes well, we will extend it,Mr ” Shumba said.

But the technology comes at cost. The initial cost is very prohibitive and could deter the wider adoption of the technology in Zimbabwe.

“The initial cost is high but over time there are huge savings to be made,” Mr Shumba said. “Once applied, you don’t have to pay for the next four years. It’s like investing in solar technologies — the initial capital outlay is huge but over time you reap the benefits. After five years, you only come to repair or plug the 20cm base of the road.

“This technology has great potential. Zimbabwe could even become the hub for the distribution of the solution in the region. We secured the distributor rights and more recently, we approached the chief researcher of the ministry of transport in Malawi to try and promote the technology.”

Early last year, the Zimbabwe National Road Administration (Zinara) disbursed $22,7 million to the country’s 60 Rural District Councils (RDCs) in order to facilitate the continued rehabilitation of rural roads.

The Government considers the country’s road network as vital to promoting industry and commerce, especially as the country targets to attain upper middle-income status by 2030.

Using the gravel road stabilisation technology, Zimbabwe might need millions of dollars for its 78 200km gravel and earth roads.

Most of the road network is in bad condition and it is worthwhile to continue to explore methods and innovations that provide lasting solutions to the maintenance and construction of rural roads.

Completion of the demos will test the viability of the gravel road stabilisation innovation and help the policy-makers to decide on the adoption of the solution for the future.

The fact that the product is non-toxic, is of critical importance, as the idea is to prevent further harm to the environment, to cut costs and promote sustainable practices in road construction.

After the trials, focus should shift towards convincing Cabinet, municipalities and councils to make use of the technology.

Should the technology be adopted, a local processing plant will be key to cut import costs and to create job opportunities locally.

Governments in some parts of the world, contractors and engineers are exploring the technology and for Zimbabwe it is worthwhile to conduct trials.

It is only through forward thinking, innovation and the willingness to embrace new technologies that will propel Zimbabwe into the fourth industrial revolution – moving into the future, creating jobs and embracing change.

Partnering local and international investors in doing trials is an important step to finding lasting solutions to the road maintenance challenges facing the country.

And, over time, if the trial proves successful, it could potentially widen the scope of use in improving access and connectivity of the rural areas.

Comments