EDITORIAL COMMENT: Upgrading mining output will build industrial base

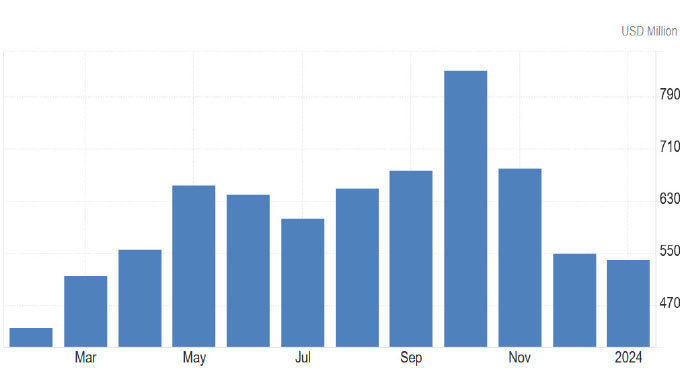

The continued rapid growth of platinum mining in Zimbabwe, with the three existing mining companies expanding operations, while four more are investing with one ready to start mining in 2024, is doing more than just expanding Zimbabwe’s mining output and growing exports.

The growth of output is now making it viable to create new investment to do more and more processing of platinum group ores in Zimbabwe, with the eventual aim of a refinery now moving from the wish list to something that is practically possible in economic terms.

The three existing companies of Zimplats, Mimosa and Unki are big, but none is big enough to move to the refining stage by itself.

A refinery needs such large investment that it only makes sense if the three co-operate and invest into a single refinery between them, and even then the operation only really works economically if production is high enough.

So they have been working out how they can work together at this end stage and Minister of Mines and Mining Development Winston Chitando is enthusiastically supporting them.

There are also monetary incentives from the Ministry of Finance and Economic Development. Miners have to pay an export tax for unrefined exports, and the latest Budget makes it clear that this is an independent tax that cannot be offset against other taxes.

Minister Chitando speaking recently as another company started the process of developing a mine said the new four licenced to mine platinum would need to process and refine their own output.

He suggested that the possibilities seemed to be to establish their own refinery, to buy into the refinery the established companies were considering, or to pay a refining fee at what should be an existing refinery once the newcomers are in production.

Any of these work, although a lot depends on the approach taken by those who build the first refinery, of whether they want to sell off some of their shareholding or compete in the contract refining business.

At present the Zimbabwean miners pay a refiner elsewhere, in fact in South Africa, to do the final refining of their output, and produce the ingots of platinum, palladium and the rarer platinum group metals that they can then sell.

Miners in Zimbabwe, if they do not have their own refinery, would have to pay someone else to do the final refining and so might as well pay a Zimbabwean refinery to do this, and so escape the modest export tax.

This means that the owners of any Zimbabwean refinery need to be competitive, and the easiest way of reducing their unit costs are to expand output and make the refinery work as hard as possible.

So there are advantages to pricing carefully to be the competitive and natural refinery for any platinum miner.

Platinum in some ways shows how the value adding can be done in stages.

The miners have moved a long way from just exporting ore. They already do a fair amount of concentrating inside Zimbabwe, something that reduces transport problems as well as adding value, and now are looking at the next stages.

Minister Chitando noted that Zimbabwe was among the lowest cost producers of platinum, thanks to the geology that made it easier to mine here than in many countries, and the large and growing skills base in Zimbabwe. While Zimbabwe has the second largest reserves in the world, it has some way to go before it can compete with the largest producers, South Africa and Russia. But it should be noted that those two countries have the local skills base.

This huge base of local skills, all the way down from top mining engineers and geologists to the staff who do the actual digging is one reason why Zimbabwe’s mining sector is expanding so rapidly, already three times what we saw in 2018, and with the growth speeding up as new mines and mine expansion come into operation.

A platinum refinery again can largely or even entirely be staffed with locals staff, at least once they have been brought up to speed on the specialist equipment and operations.

The platinum process, of gradually adding the stages of processing, can be applied to other minerals. One we talk about a lot is lithium, with a final goal being battery manufacture.

That is a final goal since there are a lot of intermediate steps between digging out the ore and making a battery, and some of those steps required a very sophisticated chemical industry to produce the compounds that go into a battery.

But this does not stop Zimbabwe moving forward in steps. Lithium is a highly-reactive metal, difficult and dangerous to store or transport as a metal, and only a tiny fraction of the world’s lithium output ends up as metal.

Most goes through successive chemical steps as a chain of salts from the compounds that come out of the rocks or the brines where it first sees the light of day to the final salts and compounds, some of which also contain cobalt, manganese and phosphorus, that go into the lithium ion polymer batteries, where most ends up.

It would seem obvious that Zimbabwe needs to move along this route step-by-step, starting with the obvious of ensuring that we can export as pure a product that comes out of the ground as possible, the basic lithium, aluminium silicon oxide salt, with no added rock.

That at least gives us top price for the basic starting point of any rock-based lithium processing.

We can then proceed to manufacture the next tier of lithium salts, in this long process of converting the salt that comes out of the ground into the salts that go into the battery.

Each step will require we upgrade our own chemical industry, and indeed the need for moving up the lithium ladder with provide incentives for upgrading our chemical industry.

In time we will need many other extensions to our chemical industry, and those we will need anyway as our industrial base becomes more sophisticated as well as larger, since we will need polymer and plastics industries.

But this sort of chemical industrial base also benefits, and can feed off, other mining operations.

While we look at mining to drive much of our present export trade and to continue being the big contributor, we also need to first increase the value of the minerals we export, by doing more processing locally, and eventually to do some of the final industrial manufacturing locally.

But while these can be seen as separate sectors, in fact it is a process to move from ore to something in its final form, and each step of that process, regardless of whether it goes into the mining or manufacturing statistics, is a gain for Zimbabwe.

Comments