BNC injects $3m in projects

Michael Tome Business Reporter

ZIMBABWE Stock Exchange listed nickel miner, Bindura Nickel Corporation (BNC), spent US$3 million in capital projects in the half year period to September 2019.

Capex projects executed in the said period by the nickel miner encompass shaft deepening, purchase of load haul dumps (LHD’s) and dump trucks.

Of the spent US$3 million the major stake went to shaft deepening that gobbled US$1,2 million while procurement of LHD’s and dump trucks consumed US$700 000 each. The shaft deepening project has been on the cards running on and off for the last decade and is expected to cumulatively chew around US$20 million on completion for commissioning this year. Sometime last year the nickel miner informed its investing public that it was directing more energy towards shaft deepening project to boost production in anticipation of increased global nickel prices.

BNC, whose 75 percent shareholding was acquired by Sotic International indicated that its refinery and the Shangani Mine project remained under care and maintenance in the period under review. In the six months up to September 2019, BNC decelerated on the smelter restart project which is still at 83 percent to completion, mainly hinged on the price of the commodity which could not meet the demanding smelter requirements, a move that made the firm’s management to unhurriedly exploit the project waiting for higher nickel price levels.

However, BNC chief executive officer Batirai Manhando, has repeatedly hinted that his company will without fail complete its long scheduled smelter construction project this year.

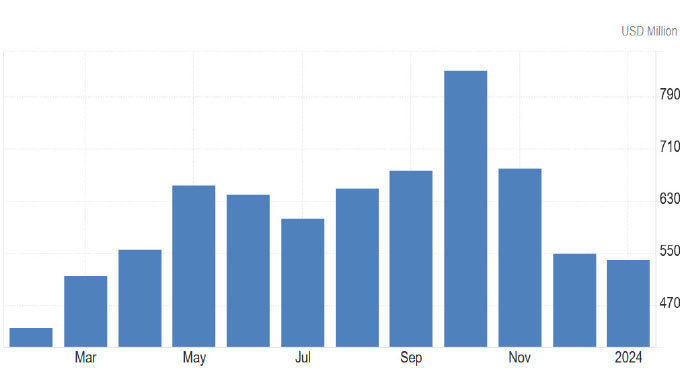

Towards end of last year the nickel producer also indicated that it was producing an average of 500 tonnes per month and was hopeful that the commodity price will be on an upward trajectory in years to come especially if the traction about electric vehicle continue to gain momentum.

“Nickel demand is expected to remain high, with a projected average growth in excess of 4 percent per annum year on year. Stainless steel will remain the main consumer of nickel and is expected to average 67 percent while the use of Nickel in the production of electric vehicles is expected to increase to 18 percent by 2025,” Mr Manhando is on record saying.

Most nickel is used for alloying elements, coatings, batteries, and some other uses, such as kitchen wares, mobile phones, medical equipment, transport, buildings, power generation and jewellery.

The electric car revolution is set to transform the nickel mining companies since the product is a major component of hybrid car batteries.

Comments